EPFL students push the boundaries of concrete engineering

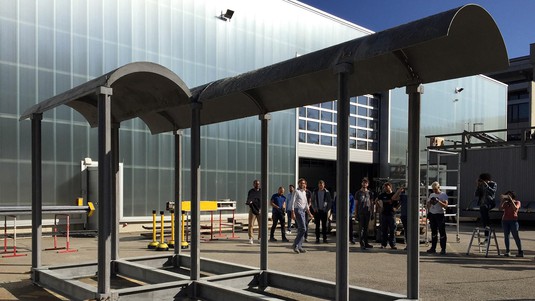

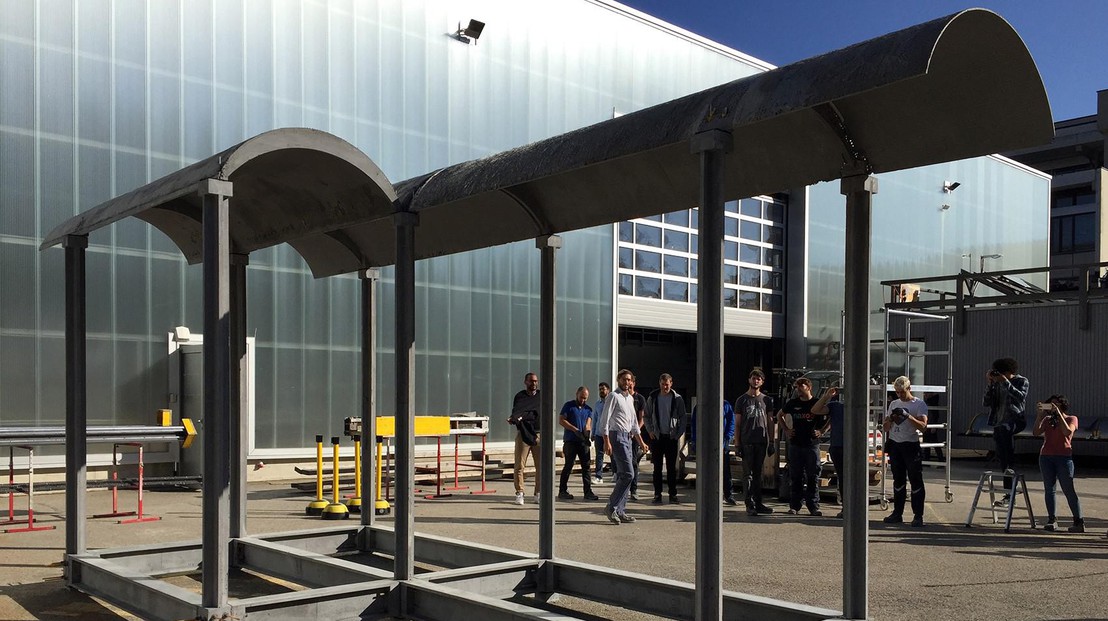

The prototype built at the Smart Living Lab in Fribourg in September 2019. © Raffael Baur

Students from EPFL and Brazil have built a ground-breaking concrete structure that sets a new benchmark for lightness and static resistance. This interdisciplinary teaching project, at the Smart Living Lab in Fribourg, is set to continue in the coming years.

In September, 26 architecture and civil engineering students from EPFL and Brazil’s Federal University of Bahia spent 14 days at the Smart Living Lab in Fribourg. The students built a prototype modular structure from textile-reinforced concrete, a material that uses carbon fiber in place of steel rods, plus purpose-built metal formwork. The pavilion is far thinner and lighter than similar conventional reinforced concrete structures – the roof shell measures just 9mm thick – without compromising on static resistance.

Promising applications

According to the staff who led the workshop, this construction technique has a bright future on account of its sustainability credentials: it uses far fewer materials than traditional methods and is compatible with low-carbon cement, resulting in sharply lower CO2 emissions. What’s more, the load-bearing sections can be taken apart and reused and are light enough to be carried by only one or two people. Ultimately, the new material could allow more people to self-build simple, weather-resistant homes without the need for heavy construction machinery.

The research is inspired by argamassa armada (reinforced mortar), a technique developed by Brazilian architect João Filgueiras Lima, known as Lélé, who specializes in the construction of favelas and prefab buildings. The new method, which replaces steel rods with carbon fiber, addresses some of the shortcomings of Lélé’s existing designs – not least the fact that many structures built from argamassa armada were prone to corrosion.

Interdisciplinary teaching

The project began four years ago as part of “Design Together,” an interdisciplinary teaching initiative at EPFL’s School of Architecture, Civil and Environmental Engineering (ENAC). The program was initially taught by five people: architects Patricia Guaita and Raffael Baur from EPFL’s ALICE Laboratory, civil engineering specialists Patrick Valeri and Miguel Fernández Ruiz from EPFL’s IBETON Laboratory, and David Fernández-Ordonez, from the International Federation for Structural Concrete (FIB). Each year, EPFL students have done their part to further research in the field through classes, semester projects and the intensive, interdisciplinary ENAC Week program.

“This pavilion is the culmination of several years of research”, says Raffael Baur. Patricia Guaita adds: “It may not look like a big deal, but it took a long time to get the design, formwork and materials just right. For architecture students, it’s really exciting to come up with a structure that seems to float in the air.” The civil engineering specialists on the team were just as pleased with the results of this initiative. “The workshop gave the students their first taste of design – and a chance to see just how complex a construction project can be in real life,” says Miguel Fernández Ruiz. “It also demonstrated the sustainable potential of concrete, given the modular and reusable features of the load-bearing structures they developed.”

Knowledge transfer

The September workshop was funded by CemSuisse, the Swiss cement industry association, and a 2018 ENAC Exploratory Grant. Sergio Ekerman, an expert from the Federal University of Bahia, traveled to Fribourg to share his expertise with the team, and CemSuisse is monitoring the research outputs with interest. The pavilion will spend the next few months outside the Smart Living Lab to see how well it withstands the harsh winter cold. Further interdisciplinary classes are planned at EPFL for the spring, when students will work on shells, base slabs and other parts of the structure.